Sidenote: some pictures have an individual description to give some specific details. All reports are best viewed on your laptop or PC.

In February 2022, a pretty ancient, yet very unique aircraft visited my homebase Luxembourg airport. Honeywell's generic flying testbed, a highly modified experimental Boeing 757-225 came all the way from Duluth, Minessota, USA, in order to carry out certain local testflights. It stayed here for 5 days before departing back to the USA again.

This old bird was delivered in 1983 to Eastern Air Lines, before it eventually ended up with Honeywell some decades later in 2005. Back then, the airplane underwent some serious modifcations to convert it into a flying test platform. None of the once so glorious and comfortable interior is left today, except for a very few seats.

The in Phoenix, Arizona based airplane is used for various research purposes in aviation technology, ranging from testing of aircraft instrumentation, engines, wheels and brakes aswell as alternate aviation fuels, airborne weather RADARs, SATCOM and so on. Furthermore, different software options for the Enhanced Ground Proximity Warning System (EGPWS), like the SmartRunway or SmartLanding RAAS (Runway Awareness and Advisory System) engineered by Honeywell are tested aboard this aircraft.

Most people only realize the "hump", so the third pylon on the airplane's right hand forward fuselage, which looks impressive, yet some kind of odd, but there is a whole lot more to discover on the inside.

When this impressive aircraft arrived in Luxembourg, the weather was not very pleasant so I decided to catch it on its first testflight two days later.

Over the keys; the mighty 757.

Great winterlight giving this jet even a sleeker appearance.

Beautiful touchdown after a one hour long test flight.

Seen here on TWY B1 during its taxi to P1.

Before we go into the more complex part inside of the airplane, we'll focus on some of the outside details of this magnificient airliner. In my personal opinion, the 757 is one of the best looking airplanes Boeing ever built until today.

Fortunately, I had some great conditions for nightshots on a crystal clear evening the same day. Even more impressive to see this jet at night with a deep dark sky in the background.

The elegant landing gear of the 75.

Impressive to be sitting under its wing.

Also found on the B744: THE RR RB211 engine.

Double trouble! 332kN of thrust resting silently on the apron.

Forward cargo compartment & "the hump".

The belly of the beast.

Perfect size: One can easily walk below the 75 and still reach access panels.

The powerful RB211 windmilling in a chilly breeze.

The B terminal and our Q400 aircraft make a nice backdrop for our special guest.

B744 taxiing by.

What a mighty tail.

The Futureshaper's tail rising proudly into a dark night sky.

No matter how splendid this machine may appear from the outside, the more interesting part of this seven-fity-seven is definitely to be found on the inside! Ready to get a rare glimpse into one of the oldest B752 still flying?

The 757 is boarded from the second door on the left side, giving you a perfect wingview while walking up the "stairway to heaven". Literally.

Let's start in the very front of the airplane by a glimpse into its old-school flightdeck. The whole cockpit and all its instruments are under video surveillance. This footage can be streamed live to the engineering stations in the back of the airplane during instrument and weather radar testing, in order to be permanently analyized by engineers. One camera is even mounted on the glareshield which points outside the forward windshield.

The most interesting part of this 757 is, however, found further in the back.

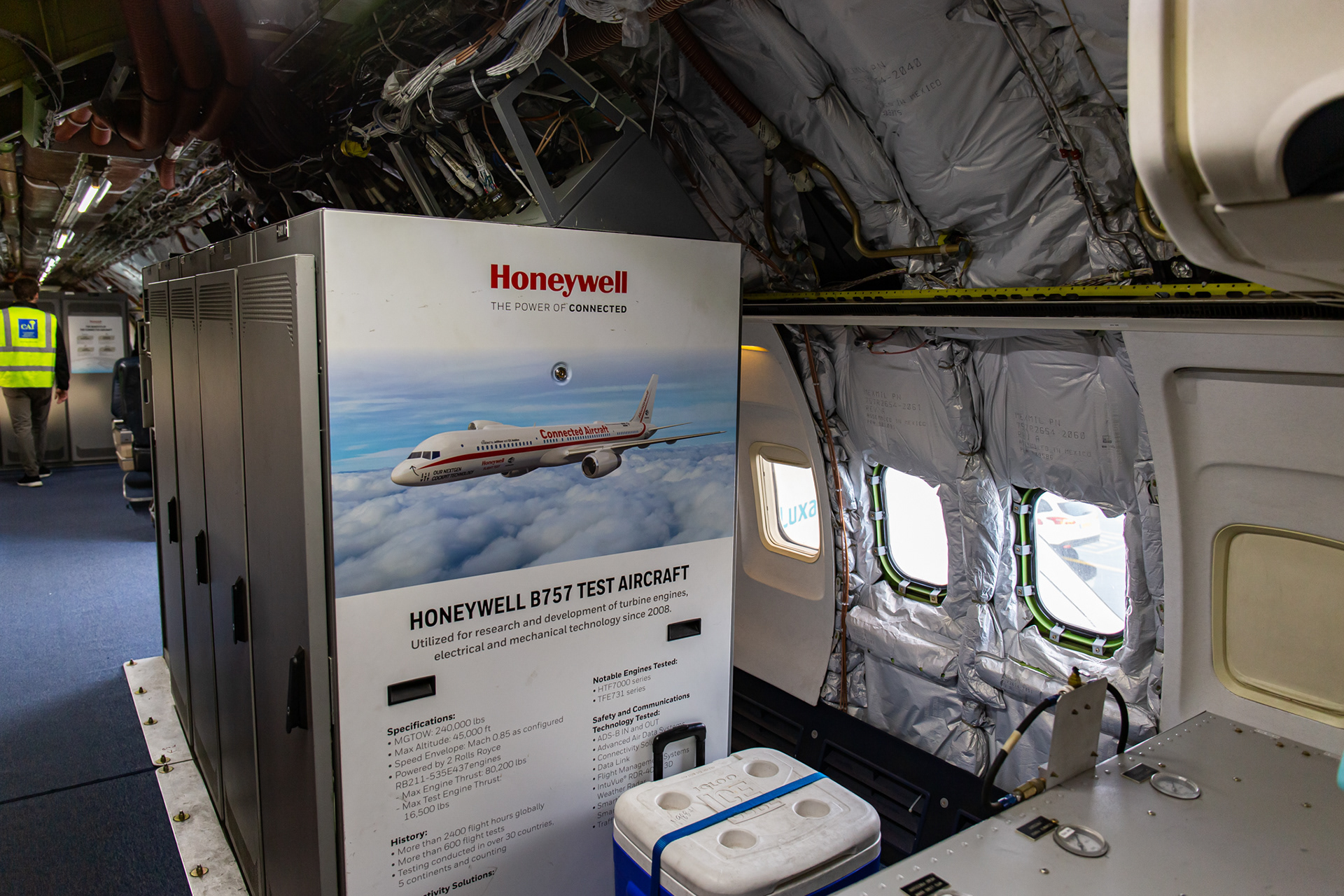

Here you'll find several engineering stations for engineers and personnel, connected to every system of the aircraft, aswell as server bays for onboard testing systems like WiFi and SATCOM for example. Next to the third pylon on the forward right hand fuselage, you'll find bays for pressure and temperature computers, ARINC data buses and so on. Therefore, all parameters of a test engine can be precisely monitored and recorded.

One question you probably ask yourself, is where that third engine is actually controlled and monitored from - all this is done from one of those stations in the back, no controls for it are to be found in the cockpit.

Engineering stations.

Bay for SATCOM & WiFi.

Some extra weight had to be put into the back of the airplane.

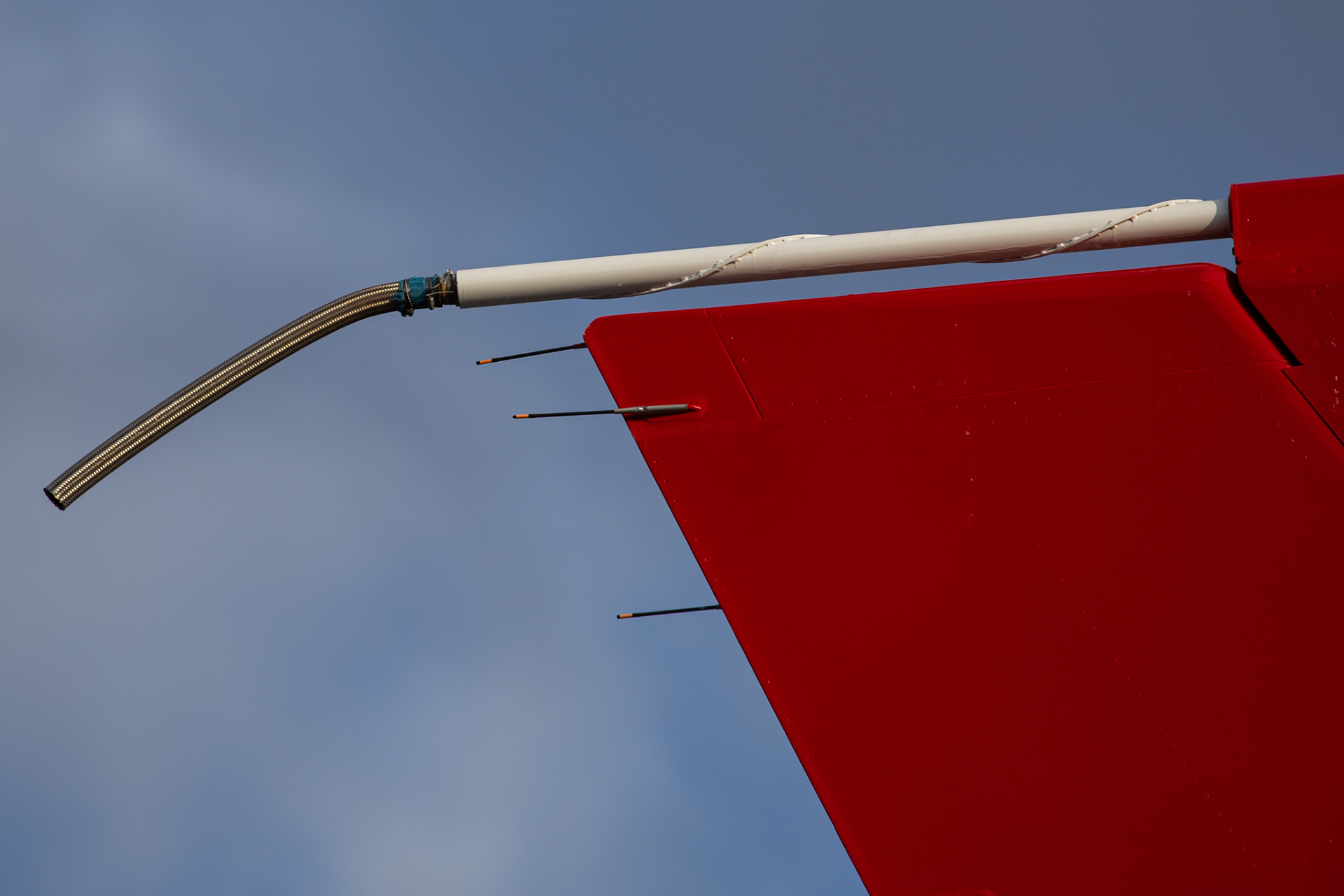

In case you wondered what that weird looking thing sticking out from the vertical stabilizer's trailing edge is used for; it is a port to release a static pressure sensor into the free airstream by a winch installed in the very back of the airplane. The reason Honeywell relies on this instrument, is because the normal static pressure ports of the airplane, due to their position, are not able to deliver precise enough static pressure data as they are not located in a perfectly unaffected airstream. In order to release the probe, the airplane has to be slowed down to 180KIAS. The length of the probe extends as far as half the wingspan of the 757.

Up high: The static pressure sensor release port.

The winch used to deploy the pressure probe.

Right now we come to the good part. Pictured below is the re-inforced airframe structure of the famous third engine attachment point. This massive construction is able to withstand thrust forces of up to 18000 pounds. Several engine types like Honeywell's HTF series, TFE731and TPE331engines have been tested on this 757. These engines, for example, can be found today on Embraer's 450/500 Legacy, Gulfstream's G280, Cessna's Citation Latitude or on the Challenger 300/350 series of Bombardier.

Having a closer look, you can see both fuel feeder lines running into the construction, from where they are routed outside into the pylon aswell as the power feeder lines for the starter generator. In between the reinforcing structure, you'll find all the wiring used to control and monitor engine parameters. This data can be fed directly into the data bays on the opposite side in the cabin for further processing and monitoring.

Very rare view to see the pylon that close. It is actually quite huge if you sit right next below it.

5 bays for the in & output of the test-engine's parameters.

The pressure sensor bay.

One more interesting thing about engine testing on this aircraft is the managing of the generated electric power by the starter generators. As this power cannot be further used, it is simply routed through big feeder lines into those three DC load bank units in the back of the airplane. Here the electrical energy is simply converted into heat and is released into the cabin, where it will eventually be carried overboard by the 757's airconditioning system.

Those boxes convert the unnecessary electrical power into heat.

Another rare glimpse, thanks to the great Honeywell team.

Definitely, this airplane is one like no other. Until today, it has undergone over 800 tests in over 30 different countries around the globe, in various conditions and temperatures. This is definitely one of the most interesting aircraft you can get on.

A big thank you goes out to the whole Honeywell Flight Test crew for this great opportunity.